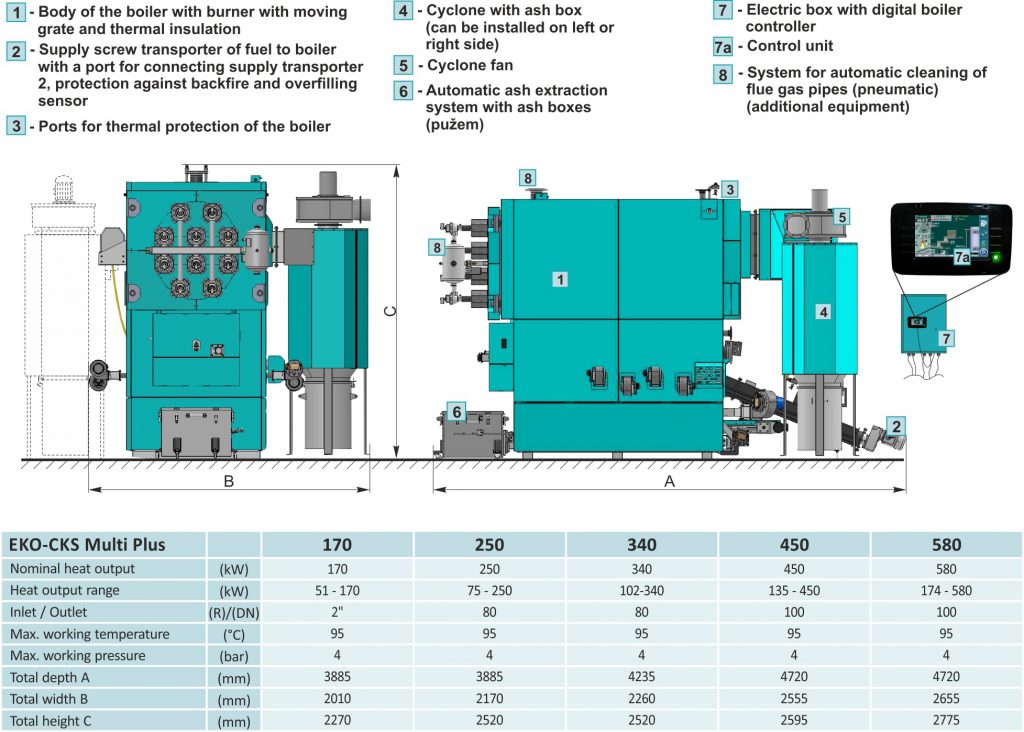

Woodchip Boiler - EKO-CKS Multi Plus (170 – 580 kW)

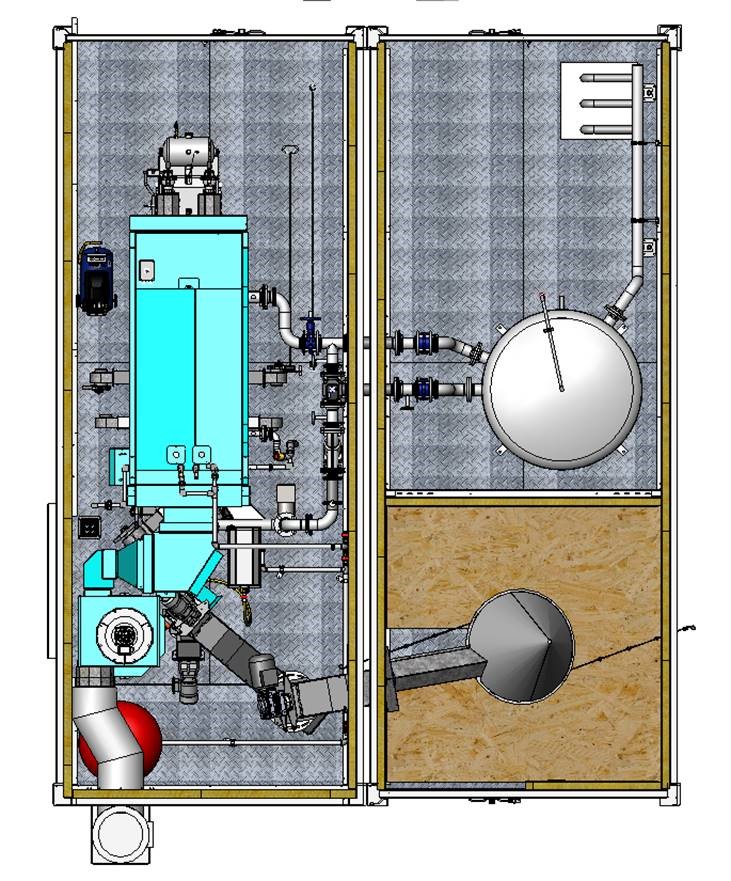

Steel warm water Woodchip Boilers EKO-CKS Multi Plus with 170 – 580 kW efficiency are designed to be fired by wood chips and wood pellets. They can be installed in both closed and open central heating systems in medium and large facilities. These boilers can also come installed in container system.

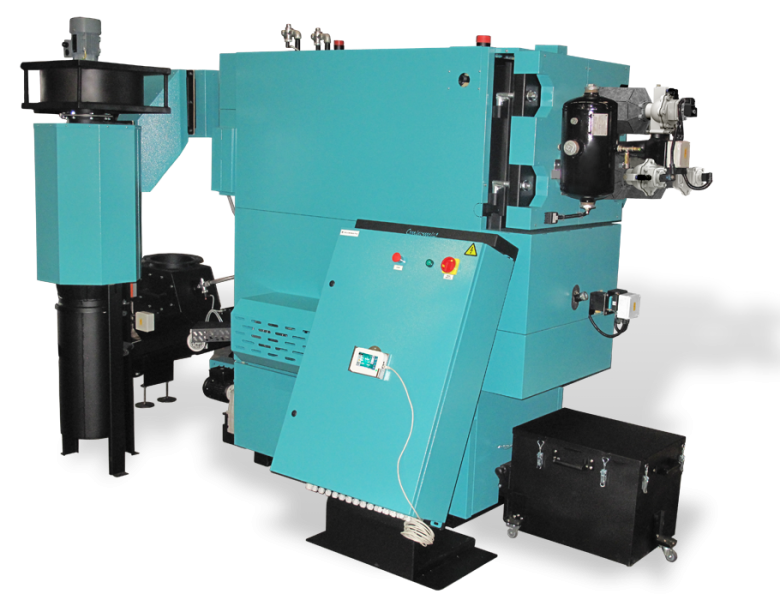

Automatic operation of these Woodchip Boilers provides the user with enviable comfort and makes the system suitable for wide application.Boilers are equipped with a moving grate for fuel burning, a lambda probe, an automatic fuel feeding system, automatic ignition, thermal protection, automatic ash removal from the combustion chamber and cyclone to extricate particles from flue gasses.

They are distinguished by a successful combination of modern technologies and quality construction materials s well as simplicity of installation and use. Proven technical solutions make these boilers safe and reliable in operation.

PRODUCT CHARACTERISTICS

SUITABLE FOR THE ENVIRONMENT

Serialized built-in cyclone for separating particles from flue gases.

ECOLOGICAL ENERGY SOURCE

Designed for wood chips and wooden pellets.

AUTOMATION

The automatic operation of these systems provides the user with enviable comfort and makes these systems suitable for wide application.

ACCESSORIES

Various accessories for specific applications: CM2K, CMNET (cascade manager), CAL, CM-GSM (alarm alert and boiler ignition / boiler via SMS) etc.

- Boiler class 5.

- They are designed to be powered by P16A/P16B – P45A, M35 (G30-G50, W35) class wood chips and E

ENplus A1 and A2 class wood pellets. - They can be installed in both closed and open central heating systems.

- After a change in type, size or moist content of the fuel it is necessary to adjust the settings of the system. There is an option of pre-adjusting the parameters for some fuel types.

- Required power supplies: 380/400 V.

- The boilers are equipped with:

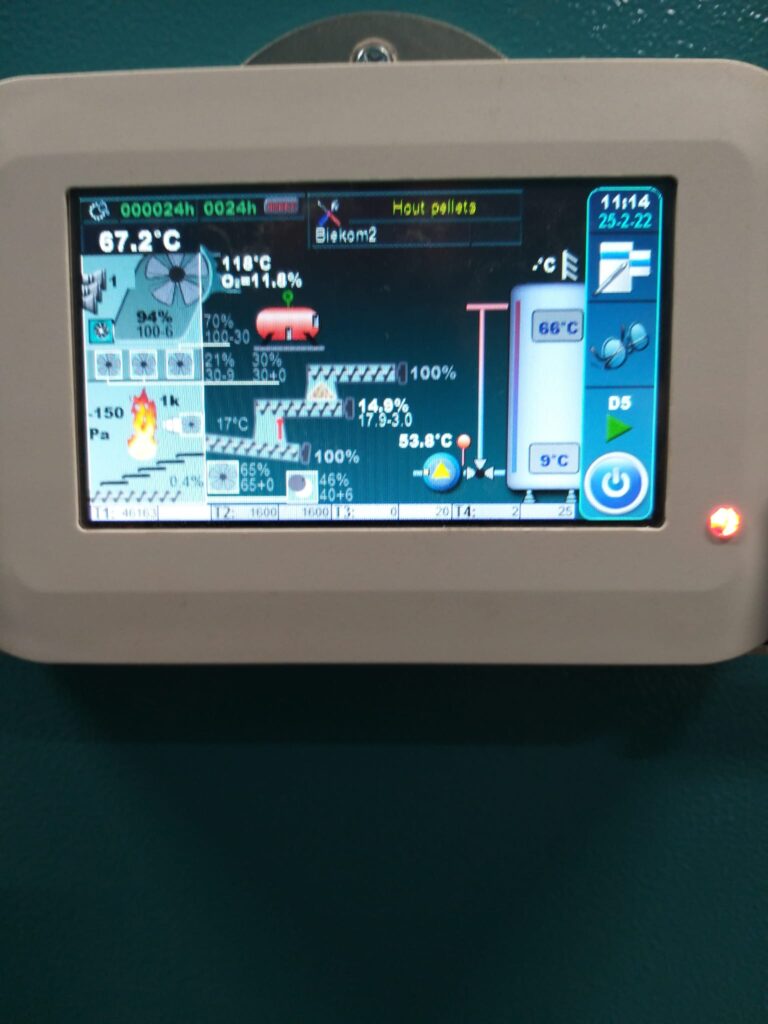

– Digital boiler control with a touch screen display which controls the operations of the boiler, fuel supply transporter and has an option to control up to two additional fuel transporters and a mixer in fuel storage.

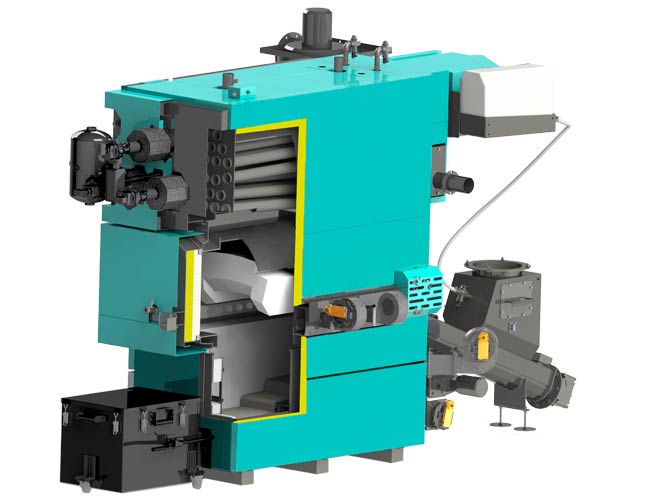

– Moving grate for fuel combustion.

– Lambda probe.

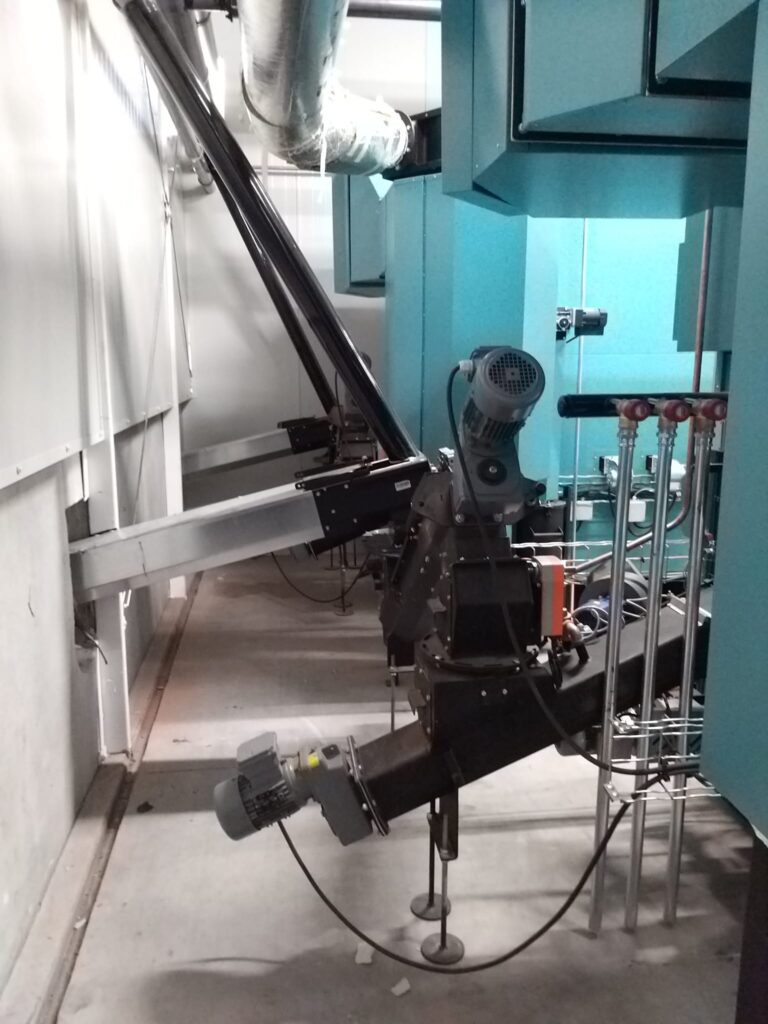

– Automatic fuel supply to burner by means of screw transporter, automatic ignition and automatic ash removal from the boiler.

– Flue gas extraction fan and cyclone for flue gas particles extrication.

– Flue gas tube turbulators, thermal protection against overheating, protection against backfire into the fuel storage (backfilling sensor, flap).

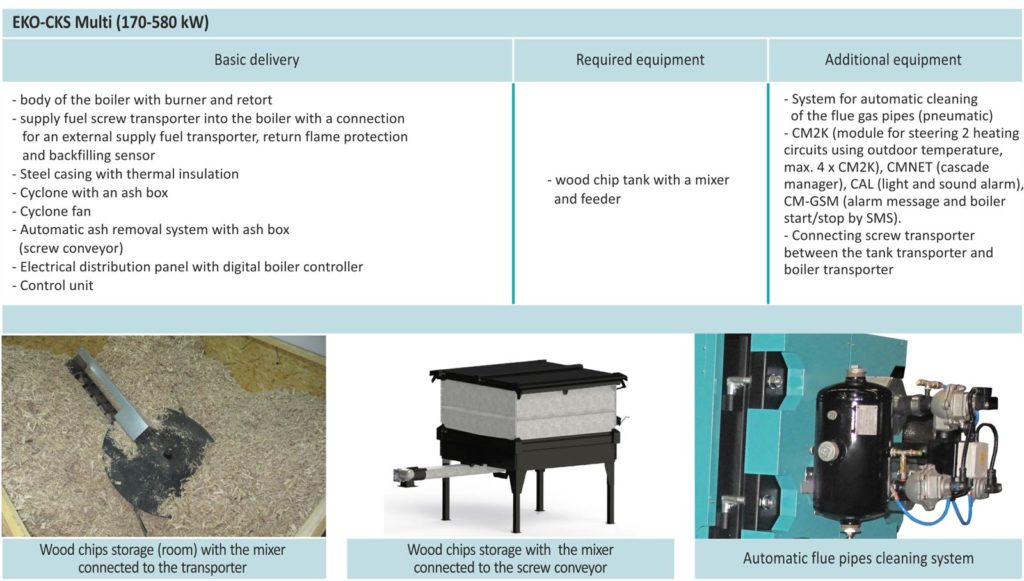

ADDITIONAL EQUIPMENT:

– automatic flue pipes cleaning system (pneumatic).

– CM2K (module for steering 2 heating circuits using outdoor temperature, max. 4 x CM2K), CMNET (cascade manager) CAL (light and sound alarm), CMGSM (alarm message and boiler start/stop by SMS).

– system for monitoring the boiler operation via PC, tablet or mobile phone.

- Corresponding burner with moving grill provides for high boiler efficiency level which makes it economical.

- Maximal work pressure of the boiler is 4 bar which makes it possible to be installed in bigger heating systems.

- Separate delivery of boiler body, cyclone with fan, automatic ash removal boxes, thermally insulated casing, power distribution cabinet with digital boiler control and cleaning set which enables easy transport, installation in the boiler room and lower damage risk.

- The boiler is manufactured in accordance with the standard EN 303-5:2012.

OBLIGATORY EQUIPMENT:

– connecting fuel conveyer.

– fuel storage: wood chips with mixer and transporter / wood pellets with transporter.

– hydraulic separator or accumulation tank.

Click on a photo below to enlarge